|

|

PEPA® Printing instructions |

Notes for PEPA® in Lithography printing:: |

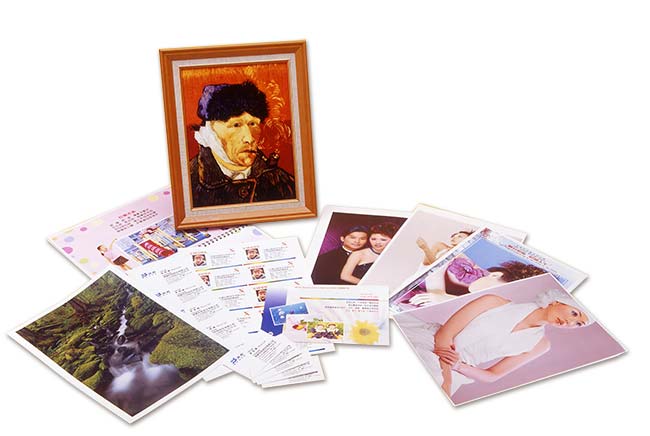

Possibility of Material Application |

|

| |

| Business cards, yearly calendars, monthly calendars, posters, press-catalogue, books, advertisement, maps, tourist guide maps, wall charts, children game diagrams,pressure sensitive labels, wrap around labels, promotion flags, scroll paintings, magazines, paper-catalogue and magazine inside paper, hanger tags, clothing tags, aviation baggage tags,pack hanger tags, lamitation facestock, medium and small shopping bags, and large shopping bags. |

|

| 1. |

The coating type of pearl paper can obtain excellent printing quality and fast ink drying when being used in offset commercial printing, but pearl paper is made of PP plastic. With the function of ink solvent, the paper will turn convex and deformed in 2-3 days (the deformation will be decreased as paper thickness increases). It is suggested you use crust ink or special ink for synthetic paper, but not non-crust ink. Also, you can still select durable, scratch resistant and high-brightness ink according to the demands of printing, the same as coated paper. If the ink you use has high viscosity, please add viscosity reducer as required. |

| |

|

| 2. |

Use special ink for synthetic paper:

If the special ink for synthetic paper is used in printing, the products of all thickness levels of pearl paper can obtain excellent printing quality and paper stability. If necessary, the paper can be mixed with special ink for synthetic paper according to the preparation. (The proportion of special ink for synthetic ink is not less than 60%). |

| |

|

| 3. |

Recommended suitable inks are as follows:

| Ink type |

Manufacturer |

Brand name |

Special ink for

synthetic paper |

Taiwan Jialong Chemical Engineering |

POP-K |

| Taiwan TOYO INK |

TSP-202 |

| Japanese KIGink Co.,Ltd |

NSPF |

| Contract Ink Co., Ltd. |

SPG NNA |

| German K+E Ink Company |

IA |

Crust ink for

common papers |

Taiwan Jialong Chemical Engineering |

GEOS-G |

| Taiwan TOYO INK |

CK WINECOO |

| Taiwan International Industry |

3F |

|

| |

|

| 4. |

When the lithography printing is in double-sided printing:

If you use common paper printing ink, please print the second side immediately after the ink dries within 24 hours after printing the first side to prevent convex deformation of the paper and inaccurate printing layout of the second side. |

| |

|

| 5. |

Suggestion on matching printing wetting water:

The wetting water requirements for the coating type of pearl paper on the offset printer is less than that of coated paper (about 10-15%), as excessive wetting water will cause a false drying phenomenon and ink emulsion phenomenon. Meanwhile, the IPA ratio in the wetting water should not be less than 13%, and the higher the PH value of the wetting water, the better the ink dryness. (The PH value is suggested to be 6.0~6.5). |

| |

|

| 6. |

Suggestion for back print prevention and stacking:

Please use the colored gray exchanger (I.C.R.) color separation principle layout to reduce the ink dosage and avoid back print. If your printing pattern requires heavy ink, appropriate drying agent is necessary. Furthermore, it is suggested to carefully select the printing pattern of the product to decide the stacking of PEPA® at the first stage of feeding PEPA®. |

| |

|

| 7. |

Suggestions for paper feeding:

PEPA® has excellent performance on the anti-static side, so if the paper is fed badly, please confirm your machining conditions, make appropriate adjustments, and complete the improvements as fast as possible. Also, when feeding the paper, reduce the sucking force of the sucking disc and the pressure of the guide wheel as much as possible to prevent paper scratching and affecting the printing quality. If your printer is provided with a static removing device, start it at the start of printing. If necessary, please improve the air blow of the printer paper feeding mechanism to prevent the paper jamming due to incomplete paper separation. |

| |

|

| 8. |

Printing room temperature:

The moisture of the printing room is best at more than 50%, because too-low relative moisture will cause static in the printing. |

| |

|

| 9. |

Powder injection:

Suitable powder injection can prevent back printing, but excessive powder injection will affect the color brightness. |

| |

|

| 10. |

Other notes:

A.Do not move the non-dried paper to prevent abnormal printing.

B.Suitably control the printing stack, because the excessive stacking of non-dried printing will cause back printing and slow drying.

C.Keep the printer and the surrounding environment clean, as dust will affect the printing quality. |

3. Non-coating Type of PEPA® |

| The non-coating type of PEPA® is a non-sucking paper surface. Please refer to the following rules for lithography printing to obtain excellent printing quality: |

| 1. |

For ink use:

Obtain excellent ink dryness: print by using special ink for synthetic paper or print using crust ink for common paper. |

| |

|

| 2. |

The recommended suitable inks are as follows:

| Ink type |

Manufacturer |

Brand title |

| Special ink for synthetic paper |

Taiwan Jialong Chemical Engineering |

POP-K |

| Taiwan TOYO INK |

TSP-202 |

| Japanese KIGink Co.,Ltd. |

NSPF |

| Contract Ink Co., Ltd. |

SPG NNA |

| German K+E Ink Company |

X-800 |

| Holland O+R Ink |

I A |

| Crust ink for common papers |

Taiwan Jialong Chemical Engineering |

GEOS-G |

| Taiwan TOYO INK |

CK WINECO |

|

| |

|

| 3. |

For the printing conditions: |

| |

| (1) |

The higher the PH value of the wetting water, the better the ink dryness. (the suggested PH value = 6.0-6.5) |

| (2) |

Amount of wetting water: as little as possible, as long as it is not dry; especially for the color block, if the printing is uneven, the reason is too much wetting water. |

| (3) |

Especially suggested for blue color block or base color printing pattern: print the blue color on the first printing seat to prevent too much water accumulation on the paper surface and avoid the caused influence on the evenness of blue printing (blue ink is special). |

| (4) |

Pay attention to the stack amount to prevent back printing and slow drying of the printing. |

|

|

| |

|

|

|