Specifications:

PEPA®:PQ-40、PQ-50、PQ-60 |

Description:

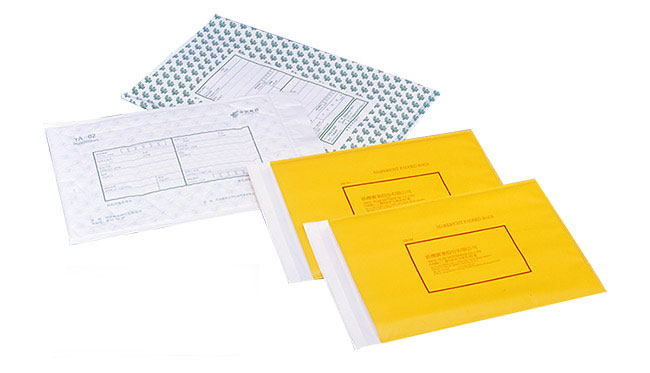

Traditional parcel and express bags are made of coated film paper. However, the composite material is not ideal with regard to recycling, bag strength, and water resistant properties. On the contrary, using PEPA® matched with a woven bags material for express bags is more ideal than natural paper because of its strength and water resistant.

※We recommend this product for the express delivery industry and postal service units.

|

Advantage: |

| 1. |

The finished bag product is high quality. |

| 2. |

It has good strength and damp-resistant. |

| 3. |

The finished product is an environmental friendly singular material, so it is recyclable. |

| 4. |

Beautiful presswork. |

Procedure:

Roll PQ grade → gravure printing → laminating with PP woven bags as PP coated film → folding bag and sealing edge → sealing bottom bag → finished product |

Possibility of Material Application |

|

| Characteristic comparison |

PEPA® |

| 1 |

Recommended

choice: |

PQ-40、PQ-50、PQ-60 |

| 2 |

Thickness 40μ~60μ |

40、50、60 |

| 3 |

Smoothness |

◎ |

| 4 |

Thickness uniformity |

◎ |

| 5 |

Coating effects |

◎ |

| 6 |

Stiffness |

◎ |

| 7 |

Proportion |

0.63 |

| 8 |

Punching and stamping |

○ |

| 9 |

Applicable temperature |

-15~120℃ |

| 10 |

Moisture resistance |

◎ |

| 11 |

Color matching and

color modulation |

X |

| 12 |

Project development |

◎ |

| 13 |

Price comparison |

○ |

| |

Contact us |

| X→No、△→OK、○→Well、◎→Excellent |