Specifications:

CAPA® Synthetic paper:BCC |

Description:

With the advancement of technology and printing techniques, articles of daily use have changed gradually. Generally, common card and paper folding toys are made out of paper, but since the paper is not water proof, moisture resistant, while having small plasticity, these products have failed to meet the demands of the people’s pursuit of entertainment!. On the contrary, the paper carving card and also other types of paper folding toys made of NAN YA PP synthetic paper, not only can break through the limitation of paper, but it is also easier to cut and bend;what’s more, is that it has the advantageous of being waterproof, durable, and being hard to deform, etc. |

Advantage: |

| 1. |

This paper is made without DIOXCIENE and in accordance with the demands of environmentally friendly materials (requirements of EN-71, RoHS, REACH, etc.), with better printing properties and without the precipitation pollution problem of DOP. |

| 2. |

It has a wider range of uses, processing temperatures, and sizes; furthermore, its characteristics include steadiness, temperature endurance, cold endurance, and weather resistance. |

| 3. |

It was developed with the R&D design characteristic of maneuvering and elasticity; different design elements, such as color, thickness, embossing, hardness, etc., can be custom manufactured. |

| 4. |

It can be cut and punched at any angle and with any space between, and the finished product cannot be easily deformed or ripped, thus allowing it to achieve the best design effects. |

| 5. |

It has good printing effects and can be adjusted through customization; furthermore, it is waterproof and does not fade in the sun. |

| 6. |

Its folding effect is fairly good, for it can be shaped while folding and will not spring back and crease. |

Product Application: |

| 1. |

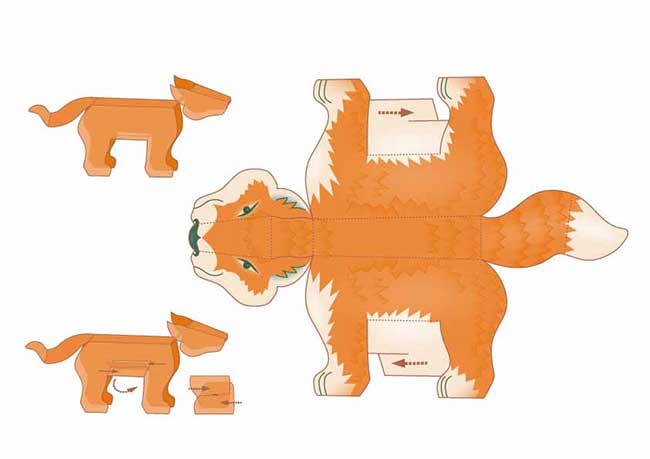

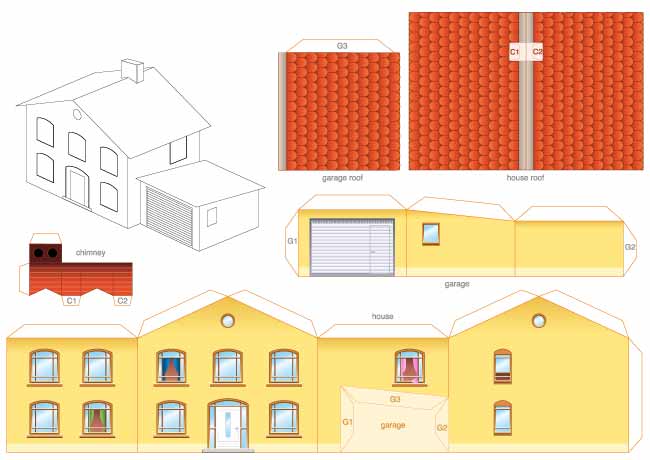

Used for all types of paper folding toys, activity masks and surrounding goods’ activity and so on. |

| 2. |

Used for paper carving artworks and DIY card making and so forth. |

Procedure:

BCC → Off-set printing → shaping → assembling →finished product

|

Possibility of Material Application |

|

| |

|

| |

|

| Item |

Unit |

BCC |

| Thickness |

μm |

350-500

(Min:250,Max:800) |

| Basic weight |

g/m2 |

566 |

| Specific gravity |

g/cm3 |

1.132 |

| Tensile strength |

Psi |

MD |

3000↑ |

| CD |

2300↑ |

| Elongation |

% |

MD |

200↑ |

| CD |

20↑ |

| Tear strength |

gm/mm |

MD |

500↑ |

| CD |

600↑ |

| ER/GR |

Dnye*cm |

44↑ |

| whiteness |

% |

84↑ |

| G.V |

ER/GR% |

2-5 |

| T.V |

% |

12↓ |

| Contact us |