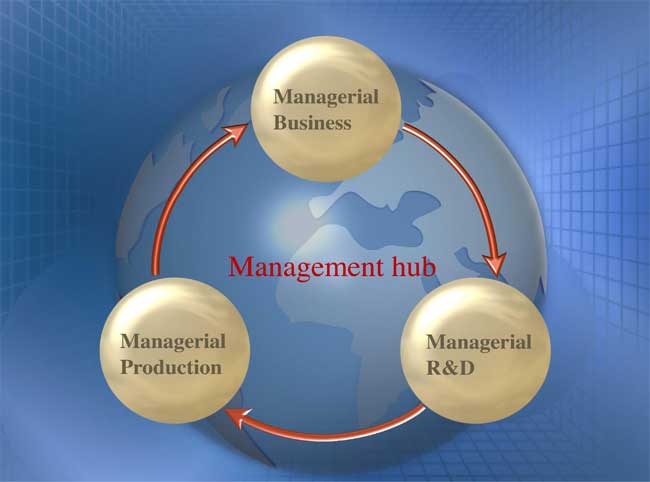

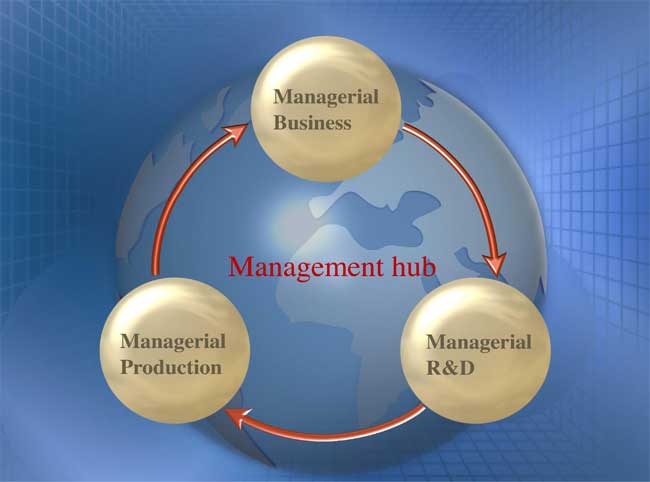

The Managerial Concepts & Operation

The Triad Of Management

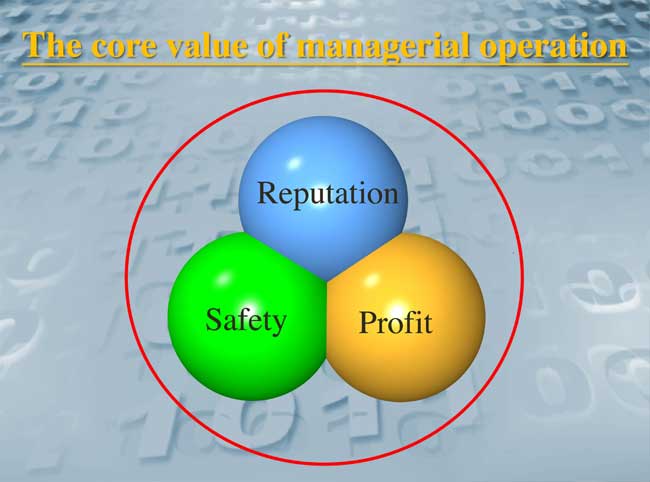

The Core Value

NAN YA PLASTICS CORPORATION, established in 1958 and affiliated with the Formosa Plastics Group, is the one of the biggest processing factories in the world. Its main products are plastic, mechanical products and polyester fiber and electronic material and other similar products.

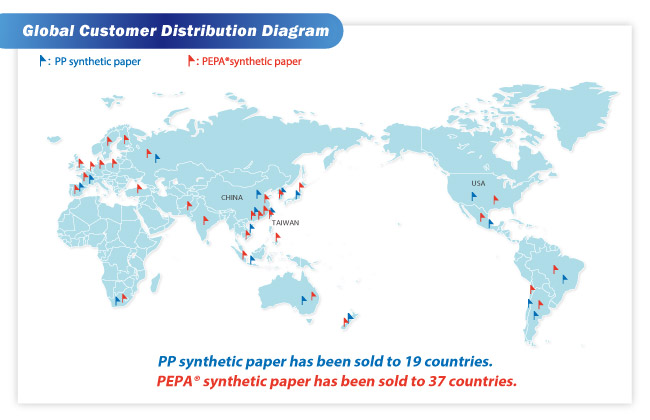

Pearl paper® (English trade name is: PEPA®) is a kind of product that brings out our third business division. It has been researched and developed from 1991 and was officially placed on the market in May of 1998 . It is a new product that is produced by paper imitating plastic material with intentions to replacing natural paper (cultural paper) with functional qualities.

Since sold, we have always adhered to the corporate philosophy of " getting into the whys and wherefores " of the Formosa Plastics Group and have always responded to the request for quality management rather strictly. Meanwhile, we manage well rounded by the philosophy of " breaking through, innovation, thoroughgoing and perfection ". At present, the application fields have exceeded more than 60 varieties. The sale at the current stage, apart from the existing applications of the synthetic paper market mainly, we have developed to replace the application of natural paper and plastic composite while treating the application of high-ranking coated paper as the principal axle of our market development.

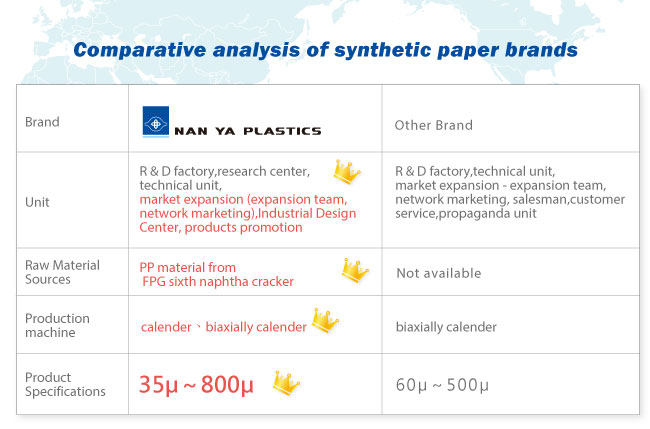

NAN YA synthetic paper is the promethean synthetic paper product of NAN YA. Its texture is similar to common paper sold on the market. That is, its texture is smooth, stiff and it is provided with the weather resistance, waterproofness of plastic as well. However, the synthetic paper produced by using polyolefin is free from halogen, so it is clean and environmentally-friendly.

Regarding the aspect of the product, NAN YA's synthetic paper is produced with single layer composite materials, but it's not ordinary YUPO or PEPA®. Therefore, it not only produces outstanding performances on its printing product, via our powerful research and development team, but the synthetic paper is endowed with more new and versatile characters, or even being developed in the area of solar back panel sheets, as well as printing building materials, TPU release paper and similarly special fields. In a word, it's a brand new product of the 21 century that is to be contended with.

The third plastic department Chiayi's second factory that was established in 1986 at the Chiayi plant area; the first set of the BOPP's main machine was put into mass production officially in 1986 with the monthly output in the initial stage being 1,250 tons.

We have three sets of BOPP and PEPA® production main machines in total, and the whole productivity has been around 5,800 tons/month; with five sets of coating equipment and a productivity of 1,630 tons/month.

Non-coating PEPA® product was finished in May, 1998 with the coating pearl paper being brought out in 2001; the water recipe of coating PEPA® was developed and finished in August, 2005 which has made a significant contribution to environmental protection.

Blow bottle in-mold labeling product was developed and finished at 2014 officially and the order at mainland region is increasing steadily and has been expanding to the global market gradually.

Being optimistic about the ASEAN market, geographic location, national policies, the ASEAN tariff and other competitive advantages, we are planning for the expansion of PEPA® production line in Nhon Trach 3 industrial zone, Dong Nai Province, Vietnam, and launching the layout of industry and worldwide sales.

The structure and characteristics of NAN YA synthetic paper is different from YUPO and PEPA® currently being sold on the market, for its main material is polyolefin, though the original mixing technology involved with research and development, produces the characteristics and customization of synthetic paper goods. From the equipment to raw material recipes, all of which are researched, developed and produced independently by NAN YA while also being provided with certifications of CNS, ISO14001 and OHSAS18001 and so on. Moreover, it has passed the SGS 163 qualifications that pronounce it free from SVHC, plasticizer, and halogen heavy metal and so on. The whole series of products are fabricated by precise production flow and is managed by a strict quality system so as to guarantee the best quality of all products and to allow all the users and consumers to enjoy the best comfortable and environmentally-friendly experience.

On the aspect of research and development, NAN YA PLASTICS CORPORATION has more than 50 years' of plastic processing experience and is set up with an independent research and development center. In addition, we have a specialized technology team toward every product and a professional market development team to conduct brand new product developments in allusion to the current market and to assist the customer to improve and be innovative. Therefore, we welcome all walks of life to explore a new oasis in the industrial circle together with NAN YA.

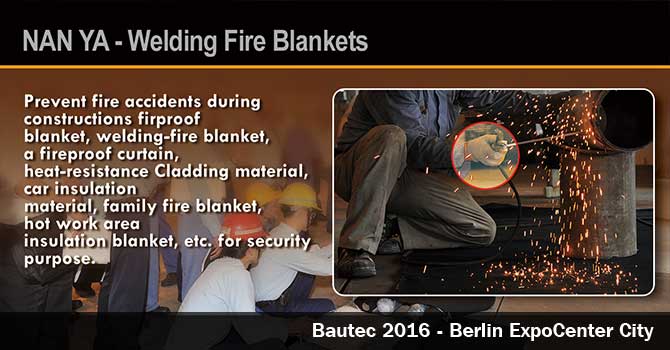

In the Berlin ExpoCenter City at the " Bautec 2016 " from Feb. 16th to 19th, 2016, we will be presenting a variety of our latest decorating and engineering material products, featuring fashionable colors with energy saving and carbon reduction technologies. We will be more than happy to exchange ideas and experiences with domestic and international traders and professionals.

Live Videos filmed on. 2016-02-24